Friday, 13 February 2026

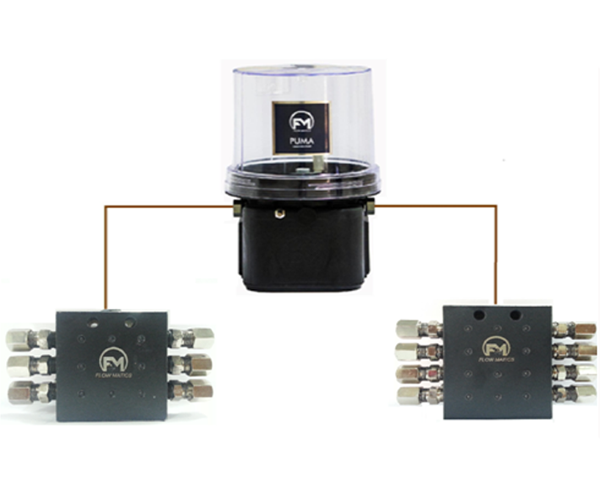

PUMA grease pumps are electrically operated and are used in progressive type automated lube systems with Divider Blocks.

The multiport pump is equipped with an eccentric cam arrangement which operates with one or more discharge element pushing grease into lubrication lines. Versatile, compact and economical, this pump can be controlled with an external controller. The pump extends machinery life, reduces operating costs and increases productivity for usage in in-plant manufacturing and mobile markets. Operates with 12 & 24V DC; Available with 6 and 10 liters reservoir.

| Type | Electric driven, 24V DC power |

| Total Pump Elements | 3 |

| Reservoir Capacity | 6 & 10 liters |

| Min. Pressure | 20 bar |

| Max. Pressure | 400 bar |

| Operating Temperature | -30 to 70 deg. C |

| Lubricant Viscosity | Grease upto NLGI 2 |

| Lube Outlet Size | 1/4” npt - F |

| Lube Outlet/ Pump element | 4 cc. |

DB series Divider Blocks are ideal for applications where space is limited. They are available in 6, 8, 10 and 12 outlet versions, each with an output of 0.2 cc. per cycle. The blocks are designed to provide a relatively simple and inepensive method of centralizing or automating the lubrication of machinery bearings. Integrated with Puma grease pump and an external controller, these divider blocks typically dispense small measured amounts of lubricant at frequent intervals while production machines are operating, ensuring trouble-free operation.

| Min. Pressure | 20 bar |

| Max. Pressure | 400 bar |

| Output Per Stroke Per Outlet | 0.2 cc/ min |

| Number of Outlets Available | 6, 8, 10 & 12 |

| Lubricante | Grease upto NLGI 2 |

| Operating Temperature | -10 to 70 deg. C |

| Lube Inlet Size | 1/8” bspt - F |

| Lube Outlet Size | 1/8” bspt - F |

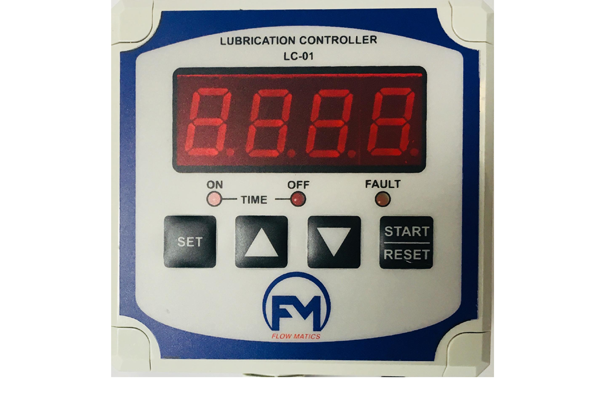

FEATURES:-

Pressure Setting: 75-175 bar

All Fittings are carbon steel compression type, which are as per DIN Standards 2353

Hoses considered are high pressure - reputed make for main line and feed Lines